Cov txheej txheem UV-curable zoo tau siv rau hauv kev tsim cov plag tsev, rooj tog, thiab txee tau ntau xyoo. Feem ntau ntawm lub sijhawm no, 100%-khoom siv thiab cov kuab tshuaj UV-curable tau yog cov thev naus laus zis tseem ceeb hauv kev ua lag luam. Nyob rau xyoo tas los no, cov txheej txheem UV-curable uas siv dej tau loj hlob. Cov resins UV-curable uas siv dej tau ua pov thawj tias yog cov cuab yeej pab tau rau cov chaw tsim khoom rau ntau yam laj thawj, suav nrog kev dhau KCMA stain, kev sim tshuaj tiv thaiv, thiab txo cov VOCs. Rau cov thev naus laus zis no kom txuas ntxiv loj hlob hauv kev ua lag luam no, ntau tus tsav tsheb tau raug txheeb xyuas tias yog cov chaw tseem ceeb uas yuav tsum tau txhim kho. Cov no yuav siv cov resins UV-curable uas siv dej ntau dua li tsuas yog muaj "yuav tsum muaj" uas feem ntau cov resins muaj. Lawv yuav pib ntxiv cov khoom muaj nqis rau cov txheej txheem, coj tus nqi rau txhua qhov chaw raws li cov saw hlau muaj nqis los ntawm cov tshuaj pleev xim mus rau lub Hoobkas thov mus rau tus neeg teeb tsa thiab, thaum kawg, rau tus tswv.

Cov chaw tsim khoom, tshwj xeeb tshaj yog niaj hnub no, xav tau ib txheej uas yuav ua ntau dua li tsuas yog dhau cov lus qhia. Kuj tseem muaj lwm yam khoom uas muab cov txiaj ntsig hauv kev tsim khoom, ntim khoom, thiab kev teeb tsa. Ib qho cwj pwm xav tau yog kev txhim kho hauv kev ua haujlwm ntawm cov nroj tsuag. Rau cov txheej txheem dej, qhov no txhais tau tias dej tso tawm sai dua thiab kev tiv thaiv kev thaiv sai dua. Lwm yam cwj pwm xav tau yog kev txhim kho kev ruaj khov ntawm cov resin rau kev ntes / rov siv dua ntawm cov txheej txheem, thiab kev tswj hwm lawv cov khoom muag. Rau tus neeg siv kawg thiab tus neeg teeb tsa, cov cwj pwm xav tau yog kev tiv thaiv zoo dua thiab tsis muaj hlau cim thaum lub sijhawm teeb tsa.

Tsab xov xwm no yuav tham txog cov kev tsim kho tshiab hauv cov polyurethanes uas siv dej los kho tau UV uas muaj kev ruaj khov zoo dua 50 ° C hauv cov xim ntshiab, nrog rau cov xim pleev xim. Nws kuj tham txog seb cov resins no hais txog cov yam ntxwv xav tau ntawm tus neeg thov txheej txheem hauv kev nce kab ceev los ntawm kev tso dej sai, kev tiv thaiv thaiv zoo dua, thiab kev tiv thaiv cov kuab tshuaj tawm ntawm kab, uas txhim kho kev ceev rau kev teeb tsa thiab ntim khoom. Qhov no tseem yuav txhim kho kev puas tsuaj tawm ntawm kab uas qee zaum tshwm sim. Tsab xov xwm no kuj tham txog kev txhim kho uas tau pom hauv kev tiv thaiv xim thiab tshuaj lom neeg tseem ceeb rau cov neeg teeb tsa thiab cov tswv.

Keeb Kwm

Cov toj roob hauv pes ntawm kev lag luam pleev xim yeej hloov zuj zus. Qhov "yuav tsum muaj" ntawm kev dhau qhov kev qhia tshwj xeeb ntawm tus nqi tsim nyog rau ib mil siv tsis txaus. Cov toj roob hauv pes rau cov xim pleev xim siv rau hauv lub Hoobkas rau cov txee, cov khoom siv sib txuas, pem teb, thiab rooj tog hloov pauv sai sai. Cov neeg tsim cov khoom uas muab cov xim pleev xim rau cov chaw tsim khoom raug thov kom ua kom cov xim pleev xim muaj kev nyab xeeb dua rau cov neeg ua haujlwm siv, tshem tawm cov tshuaj uas muaj kev txhawj xeeb siab, hloov VOCs nrog dej, thiab txawm tias siv cov pa roj carbon tsawg dua thiab cov pa roj carbon ntau dua. Qhov tseeb yog tias thoob plaws hauv cov saw hlau muaj nqis, txhua tus neeg siv khoom tab tom thov kom cov xim pleev xim ua ntau dua li tsuas yog ua tau raws li qhov kev qhia tshwj xeeb.

Pom ib lub cib fim los tsim kom muaj txiaj ntsig ntau dua rau lub Hoobkas, peb pab neeg tau pib tshawb nrhiav ntawm theem Hoobkas txog cov teeb meem uas cov neeg thov no tab tom ntsib. Tom qab ntau qhov kev xam phaj peb tau pib hnov qee cov ntsiab lus sib xws:

- Kev tso cai rau tej yam uas cuam tshuam kuv ua rau kuv lub hom phiaj nthuav dav tsis ruaj khov;

- Cov nqi nce ntxiv thiab peb cov peev nyiaj txiag tab tom txo qis;

- Cov nqi ntawm lub zog thiab cov neeg ua haujlwm tab tom nce ntxiv;

- Poob cov neeg ua haujlwm uas muaj kev paub dhau los;

- Peb lub hom phiaj SG&A ntawm peb lub tuam txhab, nrog rau cov hom phiaj ntawm kuv cov neeg siv khoom, yuav tsum tau ua tiav; thiab

- Kev sib tw txawv teb chaws.

Cov ntsiab lus no ua rau muaj cov lus hais txog tus nqi uas pib cuam tshuam nrog cov neeg siv cov polyurethanes uas siv dej UV-curable, tshwj xeeb tshaj yog nyob rau hauv kev lag luam joinery thiab cabinetry xws li: "cov chaw tsim khoom ntawm joinery thiab cabinetry tab tom nrhiav kev txhim kho hauv kev ua haujlwm ntawm lub Hoobkas" thiab "cov chaw tsim khoom xav tau lub peev xwm los nthuav dav kev tsim khoom ntawm cov kab ntau lawm luv dua nrog kev puas tsuaj tsawg dua vim yog cov txheej txheem nrog cov khoom tso dej qeeb."

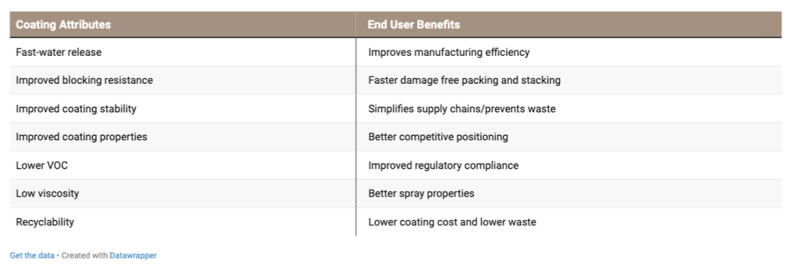

Rooj 1 qhia txog li cas, rau tus neeg tsim khoom siv cov khoom siv pleev xim, kev txhim kho hauv qee yam ntxwv thiab cov khoom siv lub cev ua rau muaj kev ua haujlwm zoo uas tus neeg siv kawg tuaj yeem ua tiav.

ROOJ 1 | Cov cwj pwm thiab cov txiaj ntsig.

Los ntawm kev tsim cov PUDs uas kho tau UV nrog qee yam ntxwv raws li teev nyob rau hauv Rooj 1, cov chaw tsim khoom siv kawg yuav muaj peev xwm daws tau cov kev xav tau uas lawv muaj hauv kev txhim kho kev ua haujlwm ntawm cov nroj tsuag. Qhov no yuav ua rau lawv muaj kev sib tw ntau dua, thiab muaj peev xwm tso cai rau lawv nthuav dav kev tsim khoom tam sim no.

Cov Txiaj Ntsig ntawm Kev Sim thiab Kev Sib Tham

Keeb Kwm ntawm UV-Kho Polyurethane Dispersions

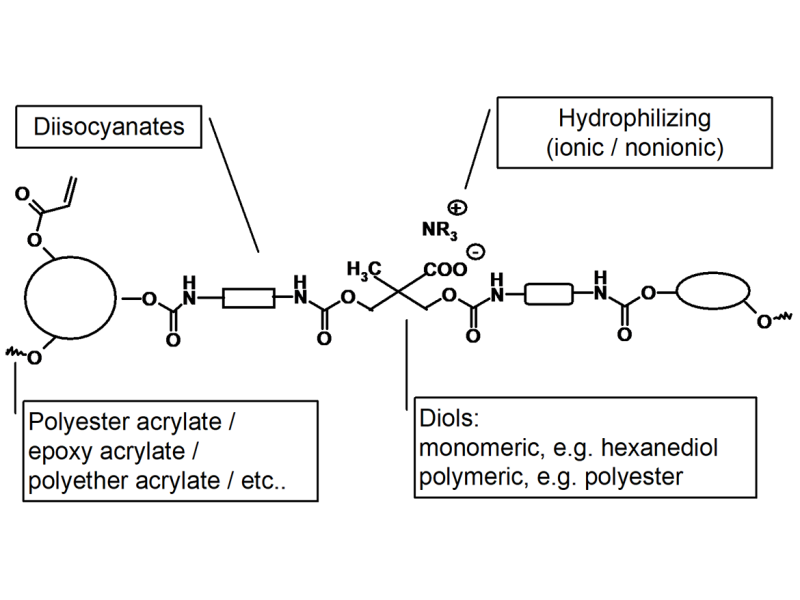

Xyoo 1990, kev siv cov anionic polyurethane dispersions uas muaj acrylate pawg txuas rau polymer hauv kev lag luam tau pib siv rau hauv kev siv hauv kev lag luam.1 Ntau yam ntawm cov ntawv thov no yog nyob rau hauv kev ntim khoom, kua mem, thiab cov txheej ntoo. Daim duab 1 qhia txog cov qauv dav dav ntawm UV-curable PUD, qhia txog yuav ua li cas cov khoom siv txheej no tau tsim.

DUAB 1 | Cov tshuaj polyurethane acrylate ua haujlwm dav dav.3

Raws li pom hauv Daim Duab 1, cov khoom siv polyurethane uas kho tau los ntawm UV (UV-curable PUDs), yog ua los ntawm cov khoom siv ib txwm siv los ua cov khoom siv polyurethane. Aliphatic diisocyanates raug tshuaj nrog cov esters, diols, hydrophilization pawg, thiab cov saw hlau txuas uas siv los ua cov khoom siv polyurethane.2 Qhov txawv yog qhov ntxiv ntawm acrylate functional ester, epoxy, lossis ethers uas koom ua ke rau hauv cov kauj ruam ua ntej-polymer thaum ua cov khoom siv dispersion. Kev xaiv cov ntaub ntawv siv los ua cov khoom siv, nrog rau cov qauv polymer thiab kev ua tiav, qhia txog kev ua tau zoo thiab cov yam ntxwv ntawm PUD. Cov kev xaiv no hauv cov ntaub ntawv raw thiab kev ua tiav yuav ua rau cov PUDs uas kho tau los ntawm UV uas tuaj yeem tsim tsis yog zaj duab xis, nrog rau cov uas tsim zaj duab xis.3 Cov hom kev tsim zaj duab xis, lossis cov hom kev ziab, yog lub ntsiab lus ntawm tsab xov xwm no.

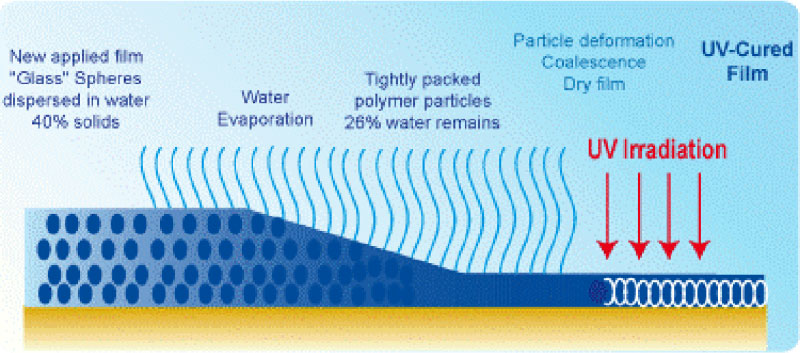

Kev tsim cov yeeb yaj kiab, lossis ziab raws li nws feem ntau hu ua, yuav ua rau cov yeeb yaj kiab sib sau ua ke uas qhuav rau qhov kov ua ntej UV kho. Vim tias cov neeg thov xav txwv tsis pub muaj kev sib kis ntawm cov txheej txheem vim muaj cov khoom me me, nrog rau qhov xav tau kev nrawm hauv lawv cov txheej txheem ntau lawm, cov no feem ntau raug ziab hauv qhov cub ua ib feem ntawm cov txheej txheem txuas ntxiv ua ntej UV kho. Daim duab 2 qhia txog cov txheej txheem ziab thiab kho ib txwm muaj ntawm UV-kho tau PUD.

DUAB 2 | Cov txheej txheem kho PUD uas kho tau los ntawm UV.

Feem ntau, txoj kev siv yog txau. Txawm li cas los xij, siv riam dov thiab txawm tias siv dej nyab. Thaum siv lawm, feem ntau yuav ua plaub kauj ruam ua ntej siv dua.

1. Flash: Qhov no ua tau ntawm chav tsev lossis qhov kub siab rau ob peb vib nas this txog ob peb feeb.

2. Qhov cub kom qhuav: Qhov no yog qhov uas cov dej thiab cov tshuaj sib xyaw raug tsav tawm ntawm lub txheej. Kauj ruam no yog qhov tseem ceeb thiab feem ntau siv sijhawm ntau tshaj plaws hauv ib qho txheej txheem. Kauj ruam no feem ntau yog ntawm >140 ° F thiab kav ntev txog 8 feeb. Kuj tseem siv tau cov qhov cub kom qhuav ntau thaj chaw.

- Teeb IR thiab cua txav: Kev teeb tsa teeb IR thiab cov kiv cua txav yuav ua kom dej ci ntsa iab sai dua.

3. UV kho.

4. Txias: Thaum twg kho tau lawm, lub txheej yuav tsum tau kho kom ntev li ib ntus kom ua tiav qhov kev tiv thaiv kev thaiv. Cov kauj ruam no yuav siv sijhawm ntev li 10 feeb ua ntej ua tiav qhov kev tiv thaiv kev thaiv.

Kev sim

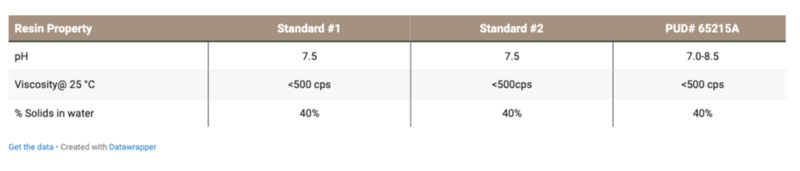

Daim ntawv tshawb fawb no piv ob lub PUDs UV-curable (WB UV), uas tam sim no siv hauv kev lag luam txee thiab joinery, rau peb txoj kev tsim kho tshiab, PUD # 65215A. Hauv daim ntawv tshawb fawb no peb piv Standard # 1 thiab Standard # 2 rau PUD # 65215A hauv kev ziab, thaiv, thiab tshuaj lom neeg tsis kam. Peb kuj ntsuas pH stability thiab viscosity stability, uas tuaj yeem tseem ceeb thaum xav txog kev siv rov qab ntawm overspray thiab lub neej txee. Qhia hauv qab no hauv Rooj 2 yog cov khoom siv lub cev ntawm txhua lub resins siv hauv daim ntawv tshawb fawb no. Tag nrho peb lub tshuab tau tsim rau qib photoinitiator zoo sib xws, VOCs, thiab qib khoom khov. Tag nrho peb lub resins tau tsim nrog 3% co-solvent.

ROOJ 2 | Cov yam ntxwv ntawm PUD resin.

Peb tau raug qhia hauv peb cov kev xam phaj tias feem ntau cov txheej WB-UV hauv cov khoom siv sib txuas thiab cov txee ua lag luam qhuav ntawm cov kab ntau lawm, uas siv sijhawm ntawm 5-8 feeb ua ntej UV kho. Los ntawm qhov sib piv, cov kab UV-based solvent-based (SB-UV) qhuav hauv 3-5 feeb. Tsis tas li ntawd, rau lub khw no, cov txheej feem ntau yog siv 4-5 mils ntub. Qhov tsis zoo loj rau cov txheej UV-curable dej thaum piv rau cov txheej UV-curable solvent-based yog lub sijhawm nws siv los flash dej ntawm cov kab ntau lawm.4 Cov teeb meem zaj duab xis xws li cov xim dawb yuav tshwm sim yog tias dej tsis tau flashed kom zoo los ntawm cov txheej ua ntej UV kho. Qhov no kuj tuaj yeem tshwm sim yog tias cov zaj duab xis ntub tuab dhau. Cov xim dawb no tau tsim thaum dej raug kaw hauv zaj duab xis thaum UV kho.5

Rau txoj kev tshawb fawb no peb tau xaiv ib lub sijhawm kho kom zoo ib yam li ib qho uas yuav siv rau ntawm kab uas siv UV-curable solvent-based. Daim duab 3 qhia peb daim ntawv thov, ziab, kho, thiab ntim khoom siv rau peb txoj kev tshawb fawb. Lub sijhawm ziab no sawv cev rau qhov kev txhim kho ntawm 50% txog 60% hauv kev ceev ntawm kab tag nrho dua li tus qauv kev lag luam tam sim no hauv kev siv joinery thiab cabinetry.

DUAB 3 | Daim ntawv thov, ziab, kho, thiab ntim khoom.

Hauv qab no yog cov kev siv thiab cov xwm txheej kho uas peb siv rau peb txoj kev tshawb fawb:

● Tshuaj tsuag rau saum ntoo maple veneer nrog lub basecoat dub.

●30 vib nas this thaum kub hauv chav tsev.

●Qhov cub kom qhuav 140 °F rau 2.5 feeb (qhov cub convection).

●Kev kho UV - qhov muaj zog li ntawm 800 mJ/cm2.

- Cov txheej txheem ntshiab tau kho siv lub teeb Hg.

- Cov xim pleev xim tau kho kom zoo siv cov teeb Hg / Ga ua ke.

● Txias 1 feeb ua ntej muab tso ua pawg.

Rau peb txoj kev tshawb fawb peb kuj tau txau peb qhov tuab ntawm cov zaj duab xis ntub sib txawv kom pom tias puas muaj lwm yam zoo xws li tsawg dua cov tsho tiv no kuj yuav raug lees paub. 4 mils ntub yog qhov ib txwm muaj rau WB UV. Rau txoj kev tshawb fawb no peb kuj tau suav nrog 6 thiab 8 mils ntub txheej daim ntawv thov.

Cov txiaj ntsig kho

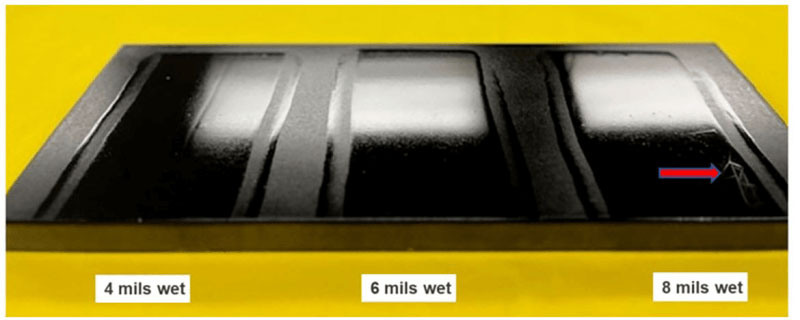

Tus Qauv #1, ib txheej txheej uas ci ntsa iab heev, cov txiaj ntsig tau pom hauv Daim Duab 4. Cov txheej txheej WB UV tau siv rau ntawm cov fiberboard nruab nrab (MDF) uas tau coated nrog ib txheej dub thiab kho raws li daim ntawv qhia hauv Daim Duab 3. Thaum 4 mils ntub cov txheej txheej dhau mus. Txawm li cas los xij, thaum 6 thiab 8 mils siv ntub cov txheej txheej tawg, thiab 8 mils tau yooj yim tshem tawm vim tsis muaj dej tso tawm ua ntej UV kho.

DAIM DUAB 4 | Tus Qauv #1.

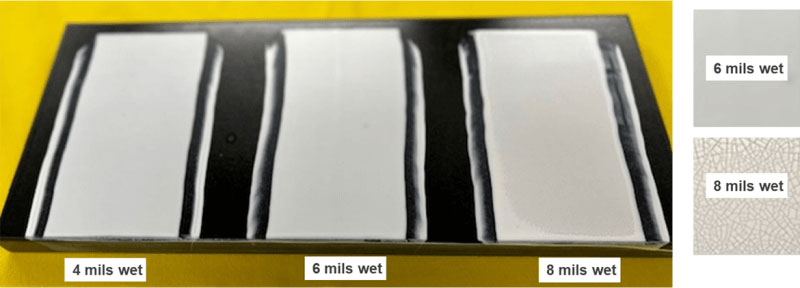

Ib qho txiaj ntsig zoo sib xws kuj pom nyob rau hauv Tus Qauv # 2, qhia nyob rau hauv Daim Duab 5.

DAIM DUAB 5 | Tus Qauv #2.

Qhia nyob rau hauv Daim Duab 6, siv tib lub sijhawm kho zoo li hauv Daim Duab 3, PUD # 65215A tau qhia txog kev txhim kho zoo heev hauv kev tso dej tawm / ziab. Ntawm 8 mils zaj duab xis ntub tuab, me ntsis tawg tau pom ntawm ntug qis ntawm cov qauv.

DUAB 6 | PUD #65215A.

Kev sim ntxiv ntawm PUD # 65215A hauv cov txheej txheem ci ntsa iab thiab cov xim pleev xim hla tib lub MDF nrog lub hauv paus dub tau raug soj ntsuam los ntsuas cov yam ntxwv tso dej tawm hauv lwm cov txheej txheem txheej txheem. Raws li pom hauv Daim Duab 7, cov txheej txheem ci ntsa iab ntawm 5 thiab 7 mils daim ntawv thov ntub dej tso tawm thiab tsim ib zaj duab xis zoo. Txawm li cas los xij, ntawm 10 mils ntub dej, nws tuab dhau los tso cov dej tawm raws li lub sijhawm ziab thiab kho hauv Daim Duab 3.

DUAB 7 | PUD ci ntsa iab #65215A.

Hauv cov mis dawb pigmented, PUD # 65215A ua tau zoo hauv tib lub sijhawm ziab thiab kho raws li tau piav qhia hauv Daim Duab 3, tshwj tsis yog thaum siv ntawm 8 ntub mils. Raws li pom hauv Daim Duab 8, zaj duab xis tawg ntawm 8 mils vim tsis muaj dej tso tawm. Zuag qhia tag nrho hauv cov qauv meej, tsis ci ntsa iab, thiab pigmented, PUD # 65215A ua tau zoo hauv kev tsim zaj duab xis thiab ziab thaum siv txog li 7 mils ntub thiab kho ntawm lub sijhawm ziab thiab kho raws li tau piav qhia hauv Daim Duab 3.

DUAB 8 | PUD Muaj Xim #65215A.

Cov Txiaj Ntsig Thaiv

Kev tiv thaiv thaiv yog lub peev xwm ntawm ib txheej kom tsis txhob lo rau lwm yam khoom uas tau coated thaum muab sib dhos ua ke. Hauv kev tsim khoom qhov no feem ntau yog qhov tsis ruaj khov yog tias nws siv sijhawm rau ib txheej kho kom ua tiav kev tiv thaiv thaiv. Rau txoj kev tshawb fawb no, cov qauv pigmented ntawm Standard # 1 thiab PUD # 65215A tau siv rau iav ntawm 5 mils ntub siv ib daim kab kos. Cov no txhua tus tau kho raws li lub sijhawm kho hauv Daim Duab 3. Ob lub iav coated panels tau kho tib lub sijhawm - 4 feeb tom qab kho cov panels tau clamped ua ke, raws li pom hauv Daim Duab 9. Lawv tseem clamped ua ke ntawm chav tsev kub rau 24 teev. Yog tias cov panels tau yooj yim sib cais yam tsis muaj kev luam tawm lossis kev puas tsuaj rau cov panels coated ces qhov kev xeem tau suav tias yog dhau.

Daim Duab 10 qhia txog qhov kev tiv thaiv kev thaiv zoo dua ntawm PUD # 65215A. Txawm hais tias ob qho tib si Standard # 1 thiab PUD # 65215A tau ua tiav kev kho tag nrho hauv qhov kev sim dhau los, tsuas yog PUD # 65215A tau qhia txog kev tso dej tawm thiab kho kom txaus kom ua tiav kev tiv thaiv kev thaiv.

DUAB 9 | Daim duab qhia txog kev sim tiv thaiv kev thaiv.

DUAB 10 | Kev tiv thaiv thaiv ntawm Tus Qauv #1, ua raws li PUD #65215A.

Cov txiaj ntsig ntawm kev sib xyaw ua ke ntawm acrylic

Cov chaw tsim khoom siv pleev xim feem ntau sib xyaw cov WB UV-curable resins nrog acrylics kom txo tus nqi. Rau peb txoj kev tshawb fawb, peb kuj tau saib kev sib xyaw PUD # 65215A nrog NeoCryl® XK-12, cov acrylic uas ua los ntawm dej, feem ntau siv los ua tus khub sib xyaw rau cov PUD uas ua los ntawm dej UV-curable hauv kev lag luam joinery thiab cabinetry. Rau kev lag luam no, kev kuaj xim KCMA yog suav tias yog tus qauv. Nyob ntawm daim ntawv thov siv kawg, qee cov tshuaj yuav tseem ceeb dua lwm tus rau cov chaw tsim khoom ntawm cov khoom coated. Qhov ntsuas ntawm 5 yog qhov zoo tshaj plaws thiab qhov ntsuas ntawm 1 yog qhov phem tshaj plaws.

Raws li tau pom hauv Rooj 3, PUD #65215A ua tau zoo heev hauv kev sim xim KCMA ua cov xim ntshiab siab, cov xim ntshiab qis, thiab ua cov xim pleev. Txawm tias thaum sib xyaw 1:1 nrog acrylic, kev sim xim KCMA tsis cuam tshuam loj heev. Txawm tias hauv kev pleev xim nrog cov neeg sawv cev xws li mustard, cov xim pleev rov qab mus rau qib uas txais tau tom qab 24 teev.

ROOJ 3 | Kev tiv taus tshuaj lom neeg thiab cov xim av (qib 5 yog qhov zoo tshaj plaws).

Ntxiv rau kev sim KCMA stain, cov chaw tsim khoom kuj tseem yuav sim kom kho tau tam sim ntawd tom qab UV kho tawm ntawm kab. Feem ntau cov teebmeem ntawm acrylic blending yuav pom tam sim ntawd tawm ntawm kab kho hauv qhov kev sim no. Qhov kev cia siab yog kom tsis txhob muaj kev tawg txheej tom qab 20 isopropyl cawv ob chav rubs (20 IPA dr). Cov qauv raug sim 1 feeb tom qab UV kho. Hauv peb qhov kev sim peb pom tias 1: 1 sib xyaw ntawm PUD # 65215A nrog acrylic tsis dhau qhov kev sim no. Txawm li cas los xij, peb tau pom tias PUD # 65215A tuaj yeem sib xyaw nrog 25% NeoCryl XK-12 acrylic thiab tseem dhau 20 IPA dr xeem (NeoCryl yog lub npe lag luam sau npe ntawm Covestro pawg).

DUAB 11 | 20 IPA txhuam ob zaug, 1 feeb tom qab UV kho.

Kev Ruaj Ntseg ntawm Cov Roj Hmab

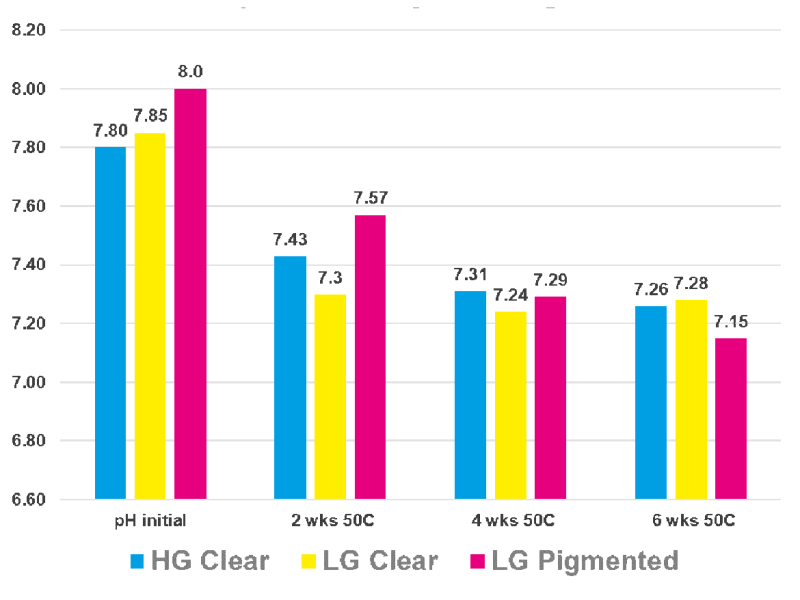

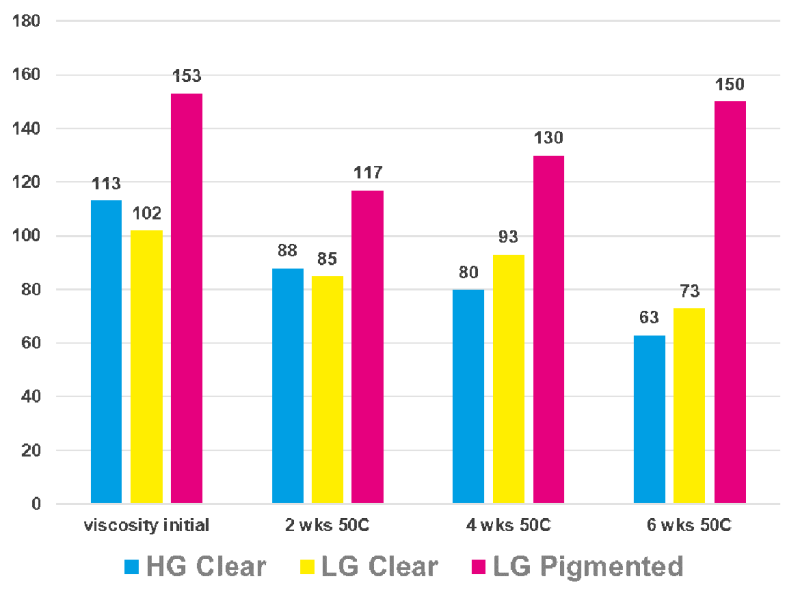

Qhov ruaj khov ntawm PUD # 65215A kuj tau raug sim. Ib qho formulation suav tias yog txee ruaj khov yog tias tom qab 4 lub lis piam ntawm 40 ° C, pH tsis poob qis dua 7 thiab qhov viscosity tseem ruaj khov thaum piv rau thawj zaug. Rau peb qhov kev sim peb tau txiav txim siab los muab cov qauv rau cov xwm txheej hnyav dua txog li 6 lub lis piam ntawm 50 ° C. Ntawm cov xwm txheej no Tus Qauv # 1 thiab # 2 tsis ruaj khov.

Rau peb qhov kev sim, peb tau saib cov xim ntshiab uas ci ntsa iab, cov xim ntshiab uas tsis ci ntsa iab, thiab cov xim uas tsis ci ntsa iab uas siv hauv txoj kev tshawb fawb no. Raws li pom hauv Daim Duab 12, qhov ruaj khov ntawm pH ntawm tag nrho peb cov qauv tseem ruaj khov thiab siab dua qhov pH ntawm 7.0. Daim Duab 13 qhia txog qhov hloov pauv viscosity tsawg kawg nkaus tom qab 6 lub lis piam ntawm 50 ° C.

DUAB 12 | pH ruaj khov ntawm cov PUD #65215A uas tau tsim.

DUAB 13 | Kev ruaj khov ntawm viscosity ntawm cov PUD #65215A uas tau tsim.

Lwm qhov kev sim uas qhia txog kev ruaj khov ntawm PUD # 65215A yog rov sim dua qhov kev tiv thaiv xim ntawm KCMA ntawm cov txheej txheem uas tau laus rau 6 lub lis piam ntawm 50 ° C, thiab piv rau nws qhov kev tiv thaiv xim KCMA thawj zaug. Cov txheej txheem uas tsis ua kom pom kev ruaj khov zoo yuav pom kev poob qis hauv kev ua tau zoo ntawm kev pleev xim. Raws li pom hauv Daim Duab 14, PUD # 65215A tswj hwm tib theem ntawm kev ua tau zoo li nws tau ua hauv kev sim tshuaj lom neeg / kev tiv thaiv xim thawj zaug ntawm cov txheej txheem pigmented qhia hauv Rooj 3.

DUAB 14 | Cov vaj huam sib luag kuaj tshuaj rau cov xim PUD #65215A.

Cov Lus Xaus

Rau cov neeg thov cov tshuaj pleev xim UV-curable water-based coatings, PUD #65215A yuav ua rau lawv ua tau raws li cov qauv kev ua tau zoo tam sim no hauv kev lag luam joinery, ntoo thiab txee, thiab ntxiv rau, yuav ua rau cov txheej txheem pleev xim pom kev txhim kho kab ceev ntau dua 50-60% dua li cov txheej txheem UV-curable water-based coatings tam sim no. Rau tus neeg thov qhov no txhais tau tias:

●Kev tsim khoom sai dua;

●Qhov tuab ntawm zaj duab xis ua rau txo qhov xav tau ntxiv cov txheej txheej;

●Cov kab ziab luv dua;

●Txuag hluav taws xob vim tsis tas yuav ziab khaub ncaws ntau;

● Tsawg dua cov khoom seem vim nws tiv thaiv tau sai;

● Txo cov khib nyiab txheej vim yog cov resin ruaj khov.

Yog tias VOCs tsawg dua 100 g/L, cov chaw tsim khoom kuj muaj peev xwm ua tau raws li lawv lub hom phiaj VOC. Rau cov chaw tsim khoom uas tej zaum yuav muaj kev txhawj xeeb txog kev nthuav dav vim muaj teeb meem kev tso cai, PUD #65215A uas tso dej sai sai yuav ua rau lawv ua tau raws li lawv cov luag haujlwm kev cai lij choj yooj yim dua yam tsis muaj kev txo qis kev ua tau zoo.

Thaum pib ntawm tsab xov xwm no peb tau hais los ntawm peb cov kev xam phaj tias cov neeg thov ntawm cov khoom siv UV-curable uas muaj kuab tshuaj feem ntau yuav qhuav thiab kho cov txheej txheem hauv cov txheej txheem uas siv sijhawm ntawm 3-5 feeb. Peb tau ua pov thawj hauv kev tshawb fawb no tias raws li cov txheej txheem qhia hauv Daim Duab 3, PUD # 65215A yuav kho tau txog li 7 mils ntub zaj duab xis tuab hauv 4 feeb nrog qhov kub ntawm qhov cub ntawm 140 ° C. Qhov no zoo nyob rau hauv lub qhov rais ntawm feem ntau cov txheej txheem UV-curable uas muaj kuab tshuaj. PUD # 65215A tuaj yeem ua rau cov neeg thov tam sim no ntawm cov khoom siv UV-curable uas muaj kuab tshuaj hloov mus rau cov khoom siv UV-curable uas muaj dej nrog kev hloov pauv me ntsis rau lawv cov kab txheej.

Rau cov chaw tsim khoom uas xav txog kev nthuav dav ntawm kev tsim khoom, cov txheej txheem raws li PUD # 65215A yuav ua rau lawv:

●Txuag nyiaj los ntawm kev siv cov kab txheej dej luv dua;

●Muaj cov kab txheej me dua hauv qhov chaw;

● Muaj kev cuam tshuam tsawg dua rau daim ntawv tso cai VOC tam sim no;

●Ua kom txuag tau hluav taws xob vim tias txo qhov xav tau ziab khaub ncaws.

Xaus lus, PUD #65215A yuav pab txhim kho kev ua haujlwm ntawm cov kab txheej UV-curable los ntawm kev ua tau zoo ntawm lub cev thiab cov yam ntxwv tso dej sai ntawm cov resin thaum ziab ntawm 140 ° C.

Lub sijhawm tshaj tawm: Lub Yim Hli-14-2024